IEEE World Haptics Conference 2021 Workshop

Abstract

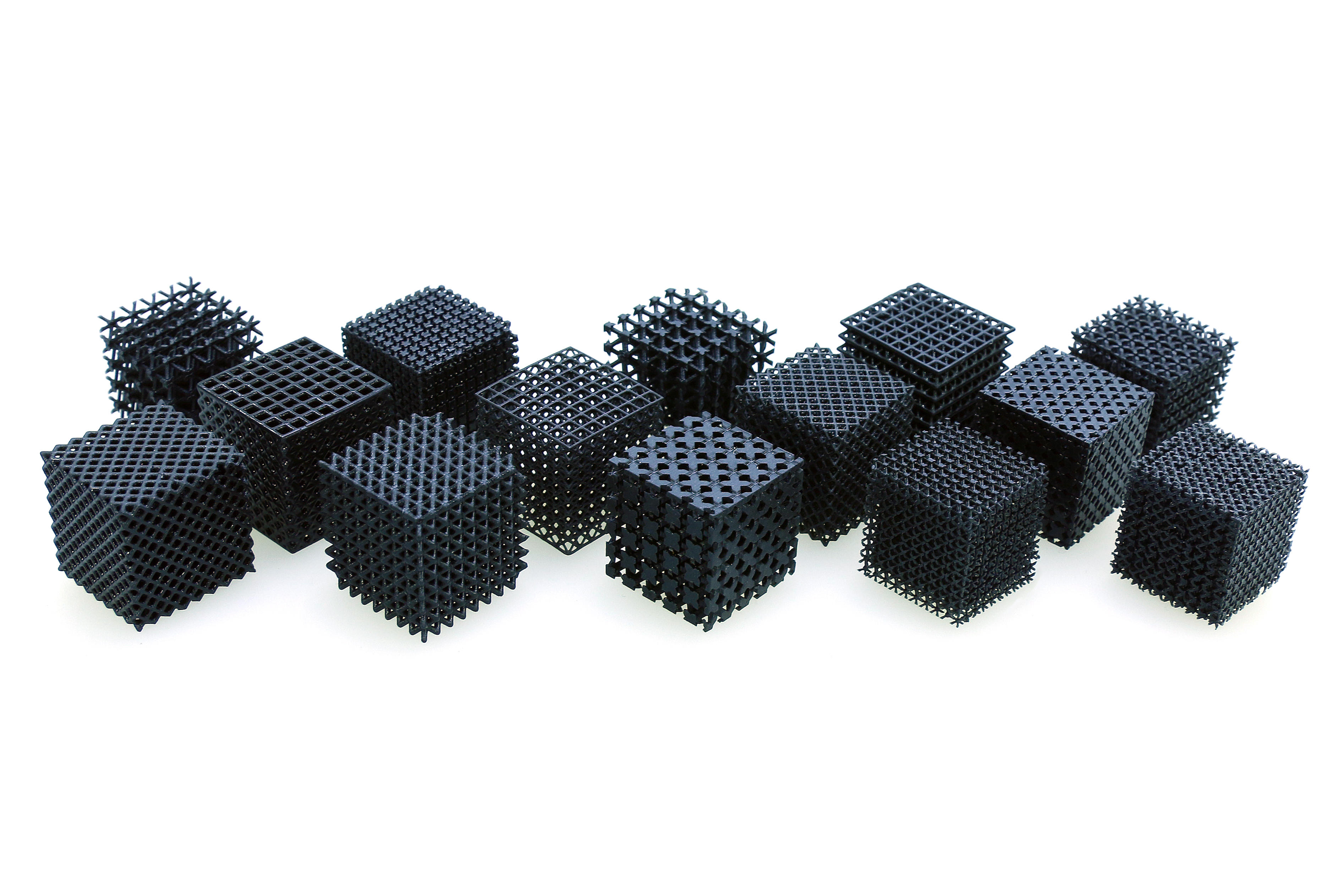

3D printing technology enables us to develop a composite shape. Recent advances in 3D printing of composite structures also contribute to fabricating a material with an inner structure, which is called architected materials. Architected materials exhibit not only mechanical functions such as elasticity, durability, and damping capacity but also aesthetic functions that make people haptically comfortable. In past research, user-study-based evaluation of tangible products is a major methodology to study product comfort. However, it would be more beneficial and time-effective if one can predict product comfort before the product is fabricated. In this panel workshop, we would like to overview recent advances in 3D printing technology that can be applied in haptic science. In digital fabrication, one can easily manipulate parameters that determine the composite shapes. Once the quantitative data on the force-displacement relationship of fabricated materials of different shape parameters is collected, we may predict the force-displacement relationship of a fabricated material to be produced by 3D printers.

We also provide an idea of how the force-displacement relationship can be connected with the sensible aspect of the product by referencing past research on sensory evaluations. In computer graphics, the Bidirectional Reflectance Distribution Function (BRDF) is widely used to render photorealistic scenes. Similarly, we can define the Force-induced Displacement Distribution Function (in short, FDDF), as a function of real variables that defines how displacement is produced by applied force to a tangible object. The FDDF is an input-output relationship in analogy with the BRDF, and can be measured from tangible objects using a calibrated force sensor and a linear actuator. Once the FDDF is measured from a real object, we can estimate the haptic perception of materials (e.g., softness) based on a previous study on softness perception. Once the FDDF is measured from a target object, in theory, we can reconstruct a shape with the target FDDF value using 3D printing technology. The simplest case is to reconstitute the force-displacement relationship at the center of a tangible object. We are going to show several examples of the reconstruction of the FDDF with various 3D printers.

In the later part of the workshop, we also introduce an industrial application of the tailor-made, digital-fabricated consumer product (e.g., insoles in a shoe) that can provide both mechanical functions and aesthetic functions for long-term use.

Figure 1 | 3D printed structures that can provide different haptic feelings in softness. Examples are fabricated by a carbon 3D printer.

Figure 2 | Other 3D-printed structures that are fabricated by the consumer 3D printers.

Figure 3 | A 3D model of a shoe insole (left) and the developed shoe insole using a 3D printer (right).

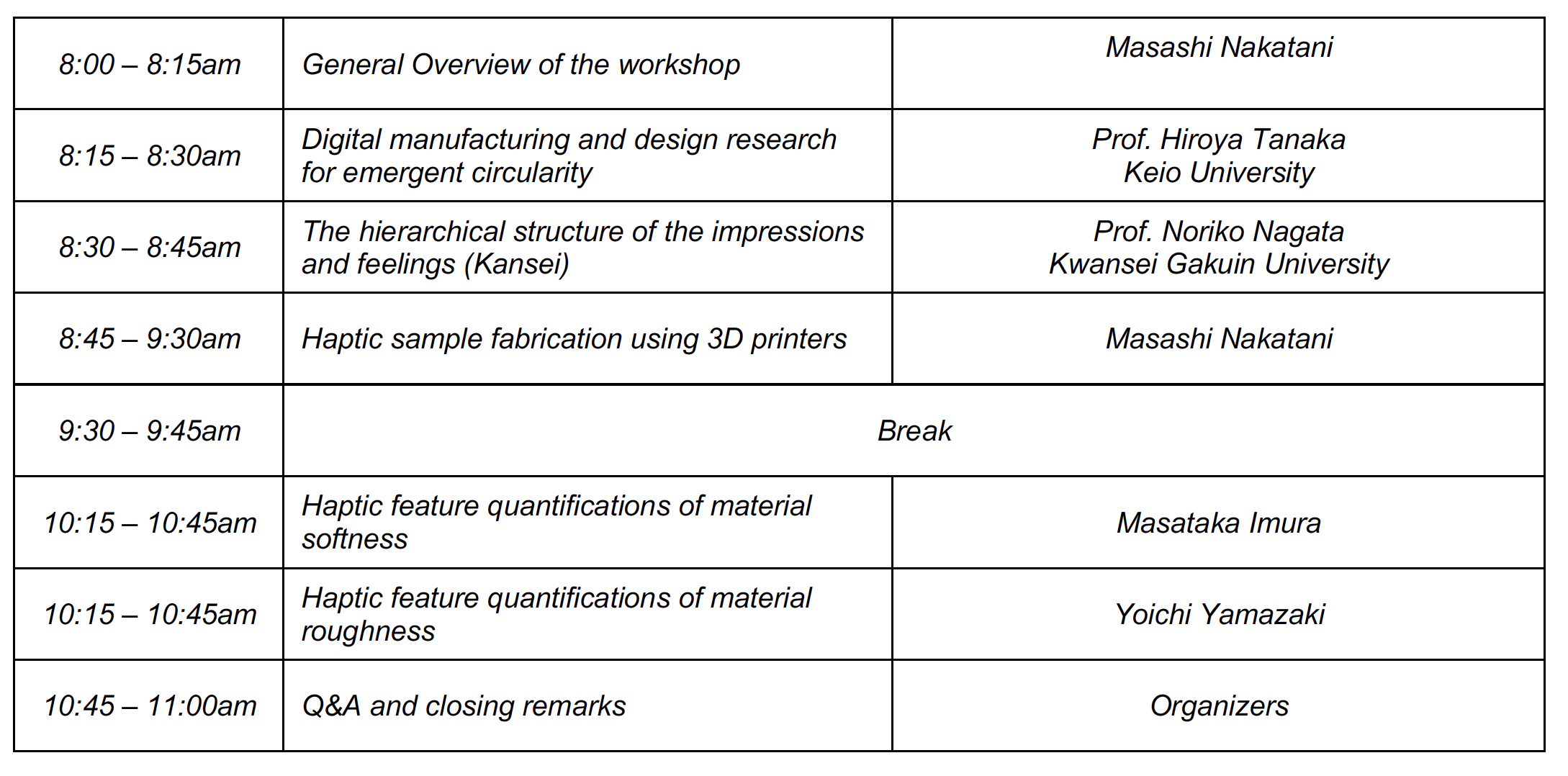

Date

July 13th, 8 AM - 11 AM Eastern Time

Tentative program

Participation

Zoom URL will be provided through the registration website at IEEE World Haptics Conference.

Organizers

Masashi Nakatani (Associate Professor, Faculty of Environment and Information Studies, Keio University)

Masataka Imura (Professor, School of Science and Technology, Kwansei Gakuin University)